Explain the Advantages of Blending Different Metal Powders.

Combining powders of different chemistries. 2To improve flow characteristics of powder particles reducing friction between particles and dies.

Powder Metallurgy Manufacturing Lts

Shape and material flexibility.

. The fine powders are mixed along with a lubricant. The powder should have good plasticity. Many different machines have been designed to handle materials with various bulk solid properties.

It should have the ability to be cold-pressed. The above figure a shows the container in which the powder to be mixed is added. Every piece of powder that enters the process is included in the finished component.

In terms of the phase of material blending is the process of solid-solid mixing or mixing of bulk solids with small. The PM process provides a host of advantages over competing metalworking technologies including. Blending achieves uniform size and shape distribution of particles within a powder.

In addition to being environmentally sound the lack of waste is a significant cost saving. What is the difference between open pores and closed pores in metallic powders. Blending powders is one of the oldest unit operations in the solid handling industries.

MEM_688 HomeWork 6 Submitted by Showmik Azam 111 Explain the advantages of blending different metal powders. Powders made by various processes have different sizes and shapes so they must be mixed to obtain uniformity. Blending is different from mixing as it is in reference to uniformly distributing particles of the same material.

To get desired physical and mechanical properties. Powder metallurgy has very little waste and no scrap. Ease of product charging operation and discharging of materials.

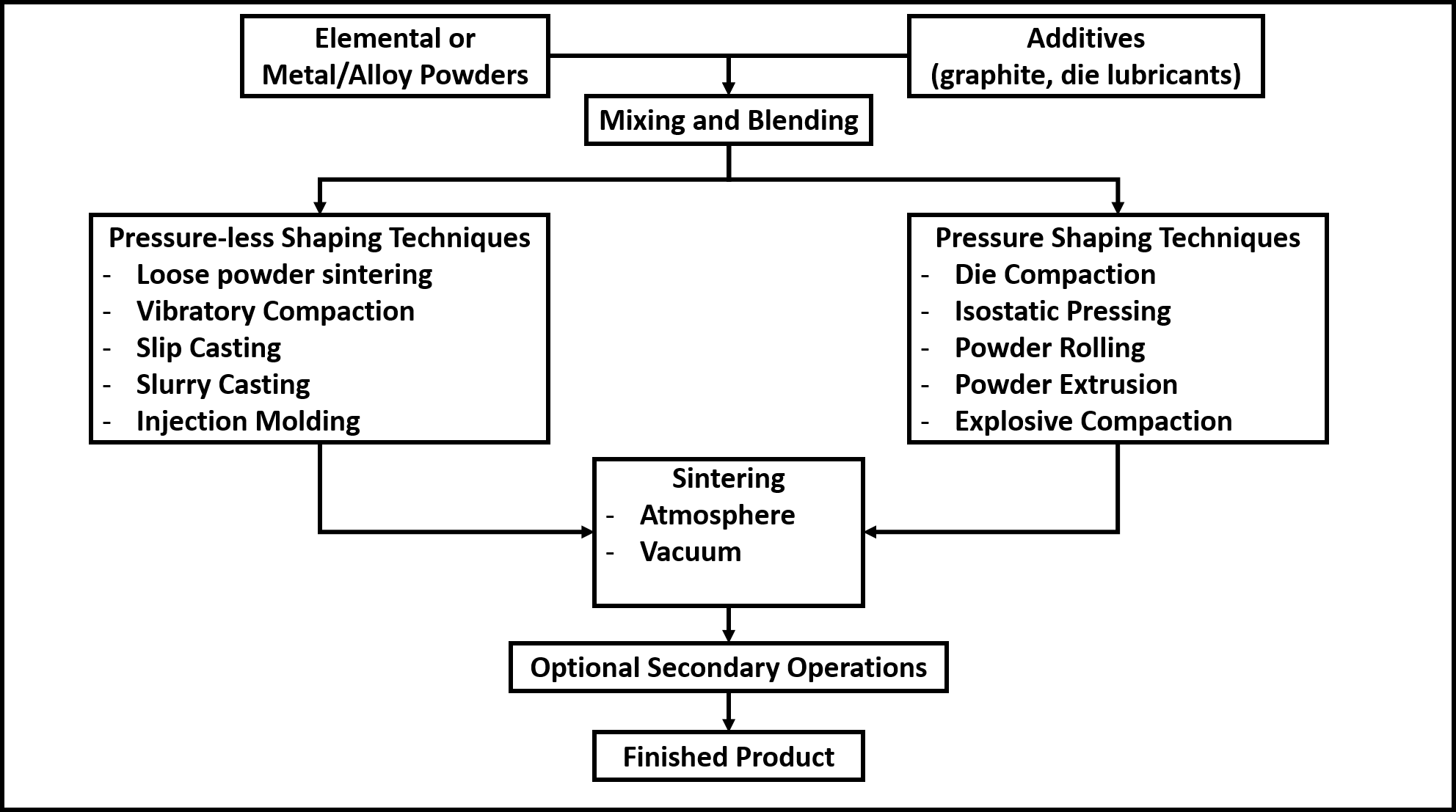

If done on a molten material the resulting spray commonly freezes into powder. The powder-metallurgy PM process depicted in the diagram below involves mixing elemental or alloy powders compacting the mixture in a die and then. A Powders can be mixed to obtain special physical mechanical and chemical characteristics.

Name some of the reasons for the commercial importance of powder metallurgy technology. Mixing powder of the same chemical composition but different sizes. 1 Metal powder preparation 2 mixing blending 3 compacting.

They are mild equipment since rotation on their axis is done slowly. The various shape of diffusiontumble blender container ensures the complete discharge of product material. Advantages of the Powder Metallurgy Process Minimizes machining by producing parts at or close to final dimensions Minimizes scrap losses by typically using more than 97 of the starting raw material in the finished part Permits a wide variety of alloy systems Produces good surface finish Provides.

C A uniform blend can impart. Give the reasons that injection molding of metal powders has become an important process. Thus diffusion mixers are suitable for friable materials.

There are many ways to atomise metal 8 but for the modern manufacturing methods discussed here the only processes widely used are water and gas atomisation. In particular while there are standard powder metal materials its also feasible to blend powders. Metal powders are blended for the following basic reasons.

Advantages of blending metal powder- 1. Powder metallurgy allows far greater flexibility in material usage and alloy choice. The terms mixing and blending are often used interchangeably but technically they are slightly different.

Atomisation is the breakup of a liquid into a fine spray. What are some of the disadvantages of the PM methods. The powder should have an excellent parking factor.

The blade continuously rotates and mixes the powder. Not only does this avoid unnecessary heating in internal mixers mills and granulating equipment but it also leads to substantial economies. Blending is a process of combining materials but blending is a relatively gentle process compared to mixing.

Further expensive dies and equipment needed to adapt this process implies that the process is justified by the unusual properties obtained in the products. Unlike other processes powder metallurgy can blend and mix different metals and nonmetals into a product. The powder metallurgy process generally consists of four basic steps.

Powder metallurgy offers the following specific advantages. 322 Mixing blending of metal powders. Powder Metal Materials Blending A Competitive Advantage from Start to Finish.

Mixing refers to combining and homogeneously distributing particles. Green strength can be important in powder metal processing. Powder metallurgy also recognized as green technology.

Blending is a process of combining materials but blending is a relatively gentle process compared to mixing. Very fine powders are obtained using various techniques. Powder metallurgy is a process which deals with product of useful components from fine metal powders from individual mixed or alloyed with or without inclusion of non-metallic constituents.

The fine powders are mixed along with a lubricant. Explain the advantages of blending different metal powders in making PM products. This allows creation of specific properties -- such as high magnetic performance for an electric motor component -- and high.

On the basis of practical experience gained by engineers with different machines the construction and. The lubricant helps in imparting good fluidity to the powders. Most PVC-U and some PVC-P compounds are initially prepared by dry blending or high-speed mixing of powders.

Powders of different metals and other materials can be mixed in order to impart special physical and mechanical properties and characteristics to the PM product. This is primarily because those metals have low melting points. Metal in powder form is costlier than in solid form.

MEM_688 HomeWork 6 Submitted by Showmik Azam 111 Explain the advantages of blending different metal powders. The blended powder is compacted in a mold or die. Blending Metal Powders Blending is carried out for the following purposes.

B Lubricants and binders can be mixed with metal powders. Conventional Powder-Metallurgy Process. In the screening of powders for sizing what is meant by the term mesh count.

For many decades powder blending has been used to homogenize bulk materials. The size of the powder particles is to pass the powder through the screen sieves having a definite number of meshes.

Powder Blending An Overview Sciencedirect Topics

Processing Of Metal Powders Ppt Download

Powder Metallurgy Process With Its Advantages And Disadvantages Mech4study

Comments

Post a Comment